In this article:

- The Stability of Industrial Computers Makes Them Ideal AI Partners for Railway Systems

- DFI's High-Wattage UPS Railway System: Fearless in the Face of Unstable Power Supply

- Modular Circuits: Ensuring DFI's Product Quality

- As AI Becomes Ubiquitous in Daily Life, DFI Strives to Be the Premier Industrial AI Partner

- Main Features of RC300-CS

- Key Features That Render the RC300-CS Ideal for AI in Railway Onboard Computing

The adoption of artificial intelligence (AI) within railway systems is on the rise. Nevertheless, the introduction of AI computing modules to industrial computers can result in a substantial surge in total power usage, potentially exceeding 300W. This heightened power consumption presents distinct challenges in devising an effective Uninterruptible Power Supply (UPS) for reliable backup power.

Railway systems have always stood as crucial transportation assets upon which people depend. Recent years have witnessed a heightened focus on energy efficiency and carbon reduction worldwide, driving countries to prioritize the upgrading of their railway networks. The International Energy Agency (IEA) has explicitly stated in its public report that if passenger and container volumes double by 2050, as projected, there will be an increased demand for energy, resulting in elevated carbon dioxide emissions and exacerbated air pollution. Further reliance on railway systems has the potential to counteract this growing trend.

Across various industries, there is a notable drive to embrace AI integration as a means of achieving “smart” enhancements, with the overarching goal of harnessing technology for precise calculations, insightful analysis, and predictive capabilities to bolster efficiency and combat carbon emissions. In parallel, the railway sector is making significant strides in integrating AI to cultivate railway systems that prioritize safety, intelligence, and efficiency. Claus Bahlmann, who leads the Siemens Mobility AI R&D team, emphasized the growing complexity of railway systems, coupled with limitations in cost and infrastructure expansion, all while ensuring the uninterrupted flow of regular railway operations. In navigating these challenges, AI emerges as the linchpin in realizing railway automation.

AI-powered railway systems are a treasure trove of benefits with significant market potential. Claus meticulously explored the advantages of AI integration within railway infrastructure, including notable reductions in downtime due to maintenance and other factors. This technology also enhances scheduling flexibility, particularly during peak travel times. Additionally, the incorporation of in-vehicle cameras offers passengers added convenience, enabling them to gauge vehicle occupancy levels and make well-informed boarding decisions. While acknowledging the persistent challenges on the path to full railway automation, Claus envisioned a future for transportation systems characterized by enhanced flexibility, unwavering reliability, and an elevated level of passenger comfort. This vision aligns seamlessly with the evolving needs of modern commuters.

Driven by the persistent demand for transportation systems that excel in safety, efficiency, cost-effectiveness, speed, and reliability, the global railway automation market is poised for continued expansion in the coming years. According to the latest report from the international research agency “The Business Research Company,” the global railway automation market is projected to achieve a size of $9.79 billion USD in the current year and is forecasted to reach $13 billion USD by 2027, driven by a robust compound annual growth rate (CAGR) of 7.4%. In terms of regional dominance, Western Europe is expected to lead the market, closely trailed by the Asia-Pacific region.

The Stability of Industrial Computers Makes Them Ideal AI Partners for Railway Systems

While “AI” may seem like a buzzword, its application in railway systems, where the safety of many is at stake, underscores the paramount importance of stability, particularly as we advance toward fully unmanned systems. A sought-after solution, capable of aligning with the expectations of industry stakeholders, revolves around a system characterised by straightforward installation, user-friendliness, and resilience in the face of adverse environmental conditions and rough terrains. In light of these critical criteria, Industrial Computers have risen to prominence as a leading choice. Industrial Computers excel in offering extended lifecycles, robust stability, and a versatile array of functions, including seamless connectivity with various peripheral devices, networking capabilities, and comprehensive power protection features.

In contrast to standard business computers, Industrial Computers stand out for their remarkable stability and durability in challenging environments, making them an ideal choice for a wide range of applications. Railway systems, in particular, often grapple with unstable power sources, making Industrial Computers exceptionally well-suited for such scenarios due to their robust voltage tolerance. For example, consider DFI’s dedicated solution, the RC300-CS, meticulously engineered for railway systems. It boasts an impressive operating voltage range, accommodating fluctuations from 9V to 36V or 77V to 137.5V.

This exceptional stability is the result of a comprehensive suite of features, including an extended operating temperature range, a fan-less design, and dust-proof/waterproof capabilities. This unwavering commitment to resilience has earned the RC300-CS multiple certifications aligning with EU railway standards, such as the esteemed electronic equipment certification EN50155, fire protection certification EN45545, and shock/vibration certification EN61373.

DFI's High-Wattage UPS Railway System: Fearless in the Face of Unstable Power Supply

DFI has showcased its prowess in power supply R&D technology through the RC300-CS, setting an industry benchmark with its integrated high-wattage Uninterruptible Power Supply (UPS) that ensures the system remains operational for up to five minutes even in the event of a power outage. This achievement is particularly notable when considering the addition of the Nvidia MXM graphics processor (GPU) module to the original computer motherboard, aimed at accelerating AI vision and machine learning graphics processing. This augmentation substantially elevates the overall power consumption, presenting challenges in UPS charging.

The RC300-CS system’s motherboard operates at a 12V input voltage, with the UPS housing three sets of lithium batteries forming a circuit that can reach an approximate 12.6V when fully charged. Under standard conditions, the UPS may not achieve full charge. Consequently, despite the theoretical capability of delivering a minimum of 12V during power interruptions, the final voltage supplied to the system may fall short due to discharge pathway losses.

With the RC300-CS supporting the MXM module, boasting a maximum power consumption of 115W, the overall system power consumption could surge to 300W upon motherboard integration. In cases of insufficient voltage levels, the system faces the risk of shutting down due to inadequate power supply.

One of the most commonly associated methods for achieving a full charge on a UPS involves the addition of a boost circuit. However, this approach not only results in increased power consumption but also generates excess heat, which can introduce greater risks to the system and escalate overall costs. In cases where the design remains unaltered, many other similar products in the industry resort to capping overall power or removing the MXM module to avert such issues. Nevertheless, these methods of power limitation or module removal come at the cost of system deployment and usage inconveniences, while also compromising the user experience.

In response to this challenge, DFI’s power supply team has employed a specialised architectural design to effectively resolve the problem. The UPS integrated into the RC300-CS ensures uninterrupted train safety while also maintaining or even enhancing cost competitiveness.

Modular Circuits: Ensuring DFI's Product Quality

In addition to leveraging research and development for the enhancement of product stability, DFI has strategically assembled an extensive collection of “modular circuits.” This treasure trove comprises over 200 distinct module circuits, each catering to specific functions. These modular circuits not only fortify DFI’s ongoing dedication to quality but also solidify its leading position within the industry.

Modular circuits play a pivotal role in standardising previous circuit designs, encompassing integrated circuits (ICs) and a diverse array of materials. These circuits are meticulously pre-defined, simplifying the research and development (R&D) process by enabling team members to swiftly locate the corresponding circuit based on product unit functions and specifications. This approach bears a striking resemblance to using “building blocks” in electric circuit design. Leveraging modular circuits in conjunction with Auto Bill of Materials (BOM) has the potential to significantly expedite R&D, potentially reducing BOM creation from days to a matter of hours.

Moreover, these modules undergo exhaustive scrutiny and refinement, overseen by a dedicated team responsible for managing and updating module versions. This rigorous approach serves as a potent catalyst for enhancing overall product quality. This impact is particularly pronounced in power supply design, where traditional methods often entail time-consuming and labour-intensive repetitive testing for validation. Modular circuits effectively streamline these laborious validation processes.

As AI Becomes Ubiquitous in Daily Life, DFI Strives to Be the Premier Industrial AI Partner

With an eye on the future, emerging technologies such as Edge AI and Artificial Intelligence of Things (AIoT) are not limited to railway systems but are progressively becoming integral parts of our daily lives. To propel the advancement of these cutting-edge technologies and meet their demanding high computing power requirements, it becomes paramount to subject them to rigorous testing. This testing encompasses essential aspects like system operational stability, heat management, and power consumption.

In the coming years, Industrial Computer R&D will place a strong emphasis on upholding stability and quality while concurrently achieving a smaller footprint, accelerated processing speeds, and heightened productivity. Building upon its existing strengths and advantages, DFI is committed to further bolstering its R&D endeavours. This includes the incorporation of smart factory practices into production processes, fostering optimization in cost-effectiveness and operational efficiency. The overarching goal is to solidify DFI’s position as the preeminent partner for industrial AI and intelligent transformation in the future.

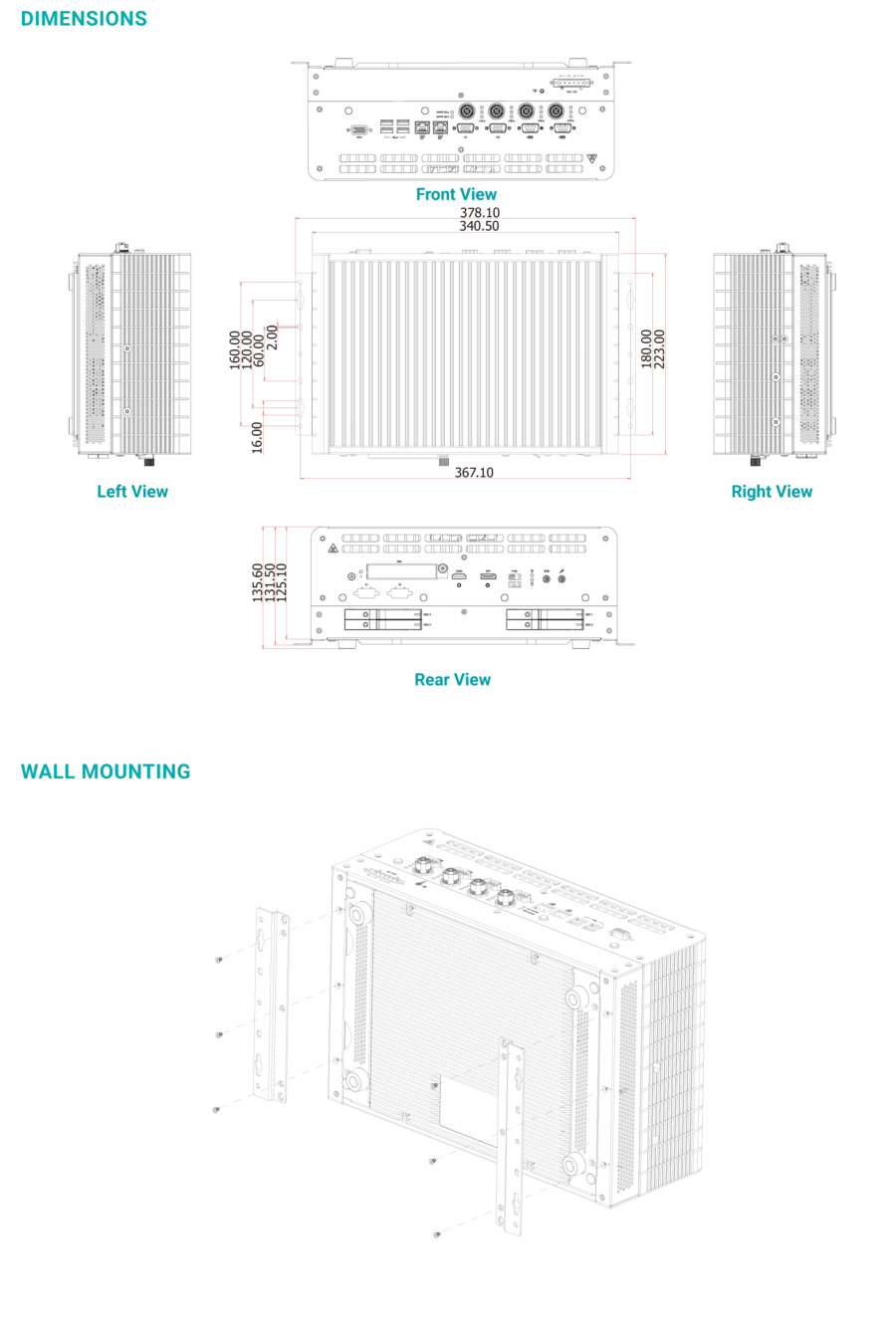

Main Features of RC300-CS

AI Edge Computing on Railway: RC300-CS With MXM & 5G

DFI’s RC300-CS is a state-of-the-art, fanless in-railway computer enriched with AI capabilities. Powered by Intel® 9th/8th Gen Core™ processors and thoughtfully integrated with NVIDIA MXM modules, the RC300-CS excels in accelerating graphic processing for AI-driven vision and machine learning applications. Moreover, its 5G capability empowers real-time communication and rapid responses, particularly at the edge of railway operations.

The RC300-CS stands as a high-performance marvel, rendering invaluable support for advanced driver assistance, predictive risk assessment, track and pantograph diagnostics, as well as onboard surveillance. Concurrently, it remains dedicated to elevating passenger comfort and safety in the midst of today’s increasingly complex rolling stock operations.

Enhanced A.I. New Force by MXM

In the dynamic realm of railways in motion, the demands of AI vision and machine learning hinge upon a copious supply of images and data. This underscores the growing indispensability of GPU technology in shaping the future of railways. The RC300-CS, equipped with a formidable MXM3.1 module, delivers processing capabilities that soar to impressive heights, boasting up to 150W power, 3072 CUDA cores and 64TFlops. These capabilities position it as a formidable force, more than capable of handling the computational demands of autonomous driving tasks.

What further sets the RC300-CS apart is its compact and robust design, engineered for optimal heat dissipation. These attributes collectively render it a superior choice among in-railway computers.5G Era Equal Real-time Data Synchronization

In the pursuit of optimizing the future railway ecosystem, the ability to efficiently transfer and analyse extensive real-time data is paramount. This highlights the pivotal role played by the 5G network, celebrated for its multi-gigabit speeds and exceptionally low latency. This technological marvel enhances device collaboration, fostering communication that is both seamless and highly efficient. It proves instrumental in enabling immediate track hazard detection and rapid emergency response.

All-inclusive Function and Interface

The RC300-CS sets itself apart by offering a versatile array of features. In addition to supporting four 15W M12 X-coded Power over Ethernet (PoE) ports and 2kV isolated Digital Input/Output (DIO) interfaces, it boasts numerous ruggedized I/O options. What’s more, the RC300-CS is equipped with multiple M.2 and mini PCIe slots, enabling seamless integration of LTE, 5G, WiFi, GNSS, CAN bus, and MVB functionalities. On top of this, it incorporates four external 2.5″ Solid State Drives (SSD), ensuring ample data storage capacity and facilitating disk array operations. This comprehensive suite of I/O choices is thoughtfully designed to cater to an array of system requirements, be it for wayside or onboard applications within the realm of train operations.

Outstanding Power Protection

Within the railway system domain, electronic power frequently transitions between diverse sources, leading to voltage fluctuations that pose stability risks. The act of powering the system on/off presents a specific vulnerability, potentially subjecting the converter to substantial voltage variations and the risk of damage. To proactively address these concerns, the RC300-CS features a power ignition function, ensuring dependable operation across a wide and uninterrupted voltage range of 9-36V or 77-137.5V. This resilient design functions as a protective shield against potential damage.

Perfect Balance Between High Performance and Heat Dissipation

Rolling stock operations often contend with substantial temperature fluctuations, and the financial repercussions of in-railway computer failures can be substantial. Enter the RC300-CS, an outstanding solution equipped with remarkable heat dissipation capabilities. It not only thrives in challenging environments but also maintains optimal functionality across an expansive temperature spectrum, ranging from -25°C to 70°C. Whether positioned beneath driver or passenger seats, it excels seamlessly, all without the need for active fans.

Reach the Unbreakable Standard

The RC300-CS proudly holds certifications from the European Union’s railway standards, including electronic equipment certification EN50155, fire protection certification EN45545, and vibrations and shocks certification EN61373. These certifications underscore its role as the railway industry’s ultimate choice for a dependable, secure, and robust embedded computer solution.

Key Features That Render the RC300-CS Ideal for AI in Railway Onboard Computing

Issue

Traditional UPS cannot fully charge in a 12V system, which could cause the system to shut down when the power supply is interrupted.

Solution

DFI uses a unique architecture to improve the RC300-CS’s UPS electric circuit and resolve the problem of it being unable to fully charge.

Result

During a power outage, it can continue to operate for at least 5 minutes, maintaining its advantage in cost competitiveness.

Other Special Features

- Expandable 5G/LTE/4G network function modules

- 4 sets of 2.5-inch solid-state drive (SSD) expansion slots

- Fan-less design supports temperature range of -25o~70o C (without MXM)

- Passed EU railway standard certifications, including electronic equipment certification EN50155, fire protection certification EN45545, and shock/vibration certification EN61373