In this article:

The Client

According to the international market analysis and consulting group IMARC Research, rapid population growth has led to a continuous increase in the demand for animal products. Projections indicate that the global animal feed market is poised to reach a substantial value of US$606.3 billion by 2028, featuring a noteworthy compound annual growth rate (CAGR) of 3.3% from 2023 to 2028. In tandem with the swift expansion of purchasing power and the need for enhanced production efficiency, there is a growing prevalence of automation in animal feed production. This trend aligns with the imperative to meet rising demand while optimising operational processes.

SIPABA stands out as a prominent manufacturer of agricultural technology automation equipment in the Mexican market. With an impressive track record of over 15 years in agricultural technology development, SIPABA has earned its status as a market leader. Specialising in providing innovative solutions to the agricultural industry, particularly in feed mills, SIPABA leverages automatic control systems and information technology. The company is dedicated to developing tailored solutions for its customers, emphasising process standardisation to optimise production. This strategic approach aims to enhance product quality while concurrently minimising production costs.

The Demands of The Application

Stable Operation in Harsh Environments

In animal feed production environments, the presence of dust and liquids is commonplace. To safeguard against potential damage from these elements infiltrating the system, it is imperative for the industrial panel PC to feature robust IP65 protection.

Given the diverse array of machinery within the factory, the risk of voltage and current interference from various equipment is significant. Therefore, it is crucial for the industrial panel PC to incorporate multiple protective measures, including safeguards against overvoltage, overcurrent, electrostatic discharge (ESD), and surges. These protections are vital to ensure the uninterrupted and reliable operation of the system amidst the complex industrial setting.

Moreover, considering the elevated temperatures typically experienced within enclosed control cabinets, a wide temperature range is essential to ensure optimal performance and longevity of the industrial panel PC in this demanding environment.

Connect with Multiple Sensors

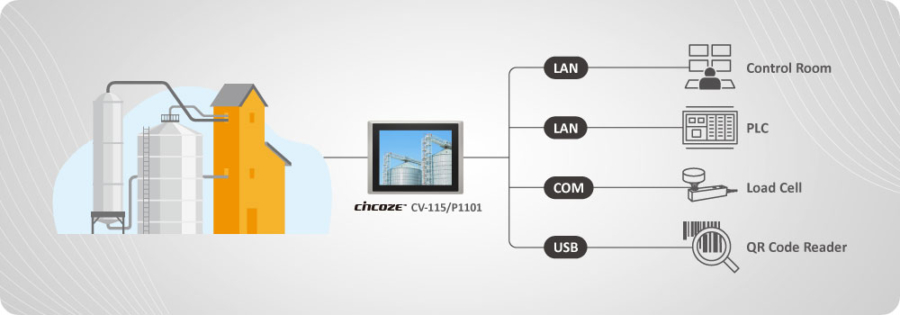

For seamless integration with on-site devices and sensors, including PLCs, load cells, QR code scanners, and more, the SCADA system necessitates ample I/O (Input/Output) capabilities to ensure comprehensive connectivity and functionality. This robust I/O configuration is essential to facilitate efficient communication and data exchange, enhancing the versatility and performance of the SCADA system in diverse industrial applications.

Easy Installation and Maintenance

To be incorporated into the control cabinet, the design of this industrial panel PC must prioritie simplicity in installation and seamless integration, all while ensuring convenient access for maintenance purposes. This approach enhances the user experience and operational efficiency, making the industrial panel PC an optimal choice for hassle-free deployment and ongoing maintenance in industrial settings.

The Solution

SIPABA has seamlessly incorporated the Cincoze industrial panel PC (CV-115/P1101) into their SCADA (Supervisory Control and Data Acquisition) system, functioning as the HMI (Human-Machine Interface). This integration serves as a pivotal link connecting to diverse sensors, facilitating the visualization, analysis, and control of the production status. Enhancing operational efficiency and providing real-time insights, this collaboration between SIPABA and Cincoze exemplifies a cutting-edge solution for streamlined industrial processes

Rugged with Industrial-grade Protections

In the industrial landscape, durability is of utmost significance for a panel PC. The CV-115/P1101 model addresses this need with a robust design, featuring an aluminum die-casting front frame and a scratch-resistant surface with a 7H hardness (P-CAP model). Tailored for factory environments, the front panel boasts IP65 waterproof and dustproof ratings, complemented by a fanless design that effectively prevents the entry of external dust and liquids.

The CV-115/P1101 goes further by incorporating a range of protective measures, including wide voltage compatibility (9-48V), safeguards against overvoltage, overcurrent, ESD, and surge. With a wide operating temperature range of 0°~65°C, this industrial panel PC ensures prolonged and stable operation even in the harshest environments. Explore the CV-115/P1101 for a reliable solution that withstands challenging industrial conditions over the long term.

Rich I/O to Meet Site Requirements

The CV-115/P1101 stands out as a sleek and fanless industrial panel PC, featuring an Intel® Atom® or Pentium® processor. This dynamic system is equipped with a diverse range of I/O interfaces, including 2x 1GbE LAN, 4x USB 3.2, 4x COM, and 8x isolated digital I/O (4in/4out). These interfaces are crucial for establishing multiple sensor connections essential for a robust SCADA system. This enables swift and efficient data collection from system equipment, providing operators with real-time information for immediate reaction and control.

Additionally, the CV-115/P1101 supports two full-size Mini-PCIe slots and one SIM slot, facilitating seamless integration of various wireless communication options and other expansion I/O connections.

CDS Patented Design for Easy Maintenance

In automated production lines, protracted downtime is economically detrimental. Therefore, the imperative for convenient maintenance and seamless upgrades becomes paramount. The Cincoze industrial panel PC (CV-115/P1101) addresses this need with its exclusive CDS patented modular design (patent number: M482908). This innovative approach is fully plug-and-play, eliminating the requirement for adjusting BIOS settings or cable connections.

In the event of an emergency, swift replacement of the monitor or computer is facilitated, hastening the resumption of production line operations and minimizing downtime. This feature also proves highly advantageous when contemplating future upgrades to enhance computer performance. With its unparalleled flexibility, the CV-115/P1101 emerges as the optimal choice for SCADA systems, ensuring efficiency and adaptability in the dynamic landscape of automated production.

Multiple Installation Methods

The Cincoze industrial panel PC series, including the CV-115/P1101, offers versatile installation options such as panel mount, VESA mount, DIN rail mount, and wall-mounted configurations. This flexibility caters to diverse installation requirements across different environments.

For enhanced performance, the CV-115/P1201 now supersedes the P1101; a higher-spec model utilising the latest Intel® Elkhart Lake platform. With support for up to 32GB DDR4 memory, the CV-115/P1201 significantly elevates computing capabilities comapred to the P1101.

The P1201 adheres as did the P10101, to the highest standards of industrial-grade protection and have achieved US UL safety certification, ensuring reliability and safety in demanding industrial settings.