In this article:

- Introduction

- Class1 Div 2 ATEX Industrial Ethernet Switches

- Understanding Class 1/Div 2 ATEX Certified Industrial Managed Ethernet Switches

- Applications of Class 1/Div 2 ATEX Certified Industrial Managed Ethernet Switches

- Oil and Gas Industry Application Examples (with Illustration)

- Benefits of Class 1/Div 2 ATEX Certified Industrial Managed Ethernet Switches

- Waterproof IP67 and M12 Ethernet Switches

- Understanding Waterproof IP67 Industrial Managed Ethernet Switches with M12 Connectors

- Applications of Waterproof IP67 Industrial Managed Ethernet Switches with M12 Connectors

- Industrial Automation Application Examples (with Illustration)

- Benefits of M12 series of Waterproof IP67 Industrial Managed Ethernet Switches with M12 Connectors

- Benefits of Waterproof IP67 Industrial Managed Ethernet Switches with M12 Connectors

- IEC 61850-3 Certified Industrial Ethernet Switches

- Understanding IEC 61850-3 Certified Industrial Managed Ethernet Switches

- Power Utility Substation Automation Application Example (with Illustration)

- Benefits of IEC 61850-3 Certified Industrial Managed Ethernet Switches:

Introduction

Antaira Technologies, a trusted Official Assured Systems Partner, is at the forefront of providing cutting-edge industrial networking solutions. Specialising in Class 1 Division 2 ATEX certified, Waterproof IP67, and IEC 61850-3 certified devices, Antaira offers a comprehensive range of Industrial Ethernet Switches that thrive in rugged temperatures and extreme environments.

This article delves deeper into the superior features of a selection of these Industrial Ethernet Switches and explores the diverse applications in which they have been successfully deployed.

Unparalleled Reliability in Extreme Environments:

Antaira’s Industrial Ethernet Switches are designed to withstand the harshest conditions in a wide range of industries. Their ATEX certification guarantees safe operation in potentially explosive atmospheres, making them a go-to choice for oil refineries, chemical plants, and hazardous industrial settings. Moreover, the switches are waterproof with an IP67 rating, ensuring flawless performance even in water-submerged applications, such as marine vessels, outdoor surveillance systems, and wastewater treatment plants.

Seamless Communication and Enhanced Efficiency:

One of the standout features of Antaira’s Industrial Ethernet Switches is their ability to create reliable communication networks, supporting various protocols like Modbus TCP, PROFINET, and EtherNet/IP. This seamless integration allows for efficient data exchange, real-time monitoring, and streamlined automation processes in manufacturing plants, power generation stations, and transportation systems.

Flexible Network Configurations:

Antaira understands that every industrial setup has unique networking requirements. Hence, their Industrial Ethernet Switches come with a wide array of port configurations, including copper, fibre, and PoE (Power over Ethernet) options. This versatility ensures that network administrators can effortlessly deploy the switches in diverse infrastructures, such as oil rigs, railway networks, and smart grid systems.

Redundancy and Resilience:

Downtime can be catastrophic in critical infrastructures. Antaira addresses this concern by equipping their Industrial Ethernet Switches with advanced redundancy features, such as Rapid Spanning Tree Protocol (RSTP) and Media Redundancy Protocol (MRP). These protocols enable rapid network recovery and seamless switchovers, reducing the risk of system failures and ensuring continuous operations in power substations, mining sites, and transportation hubs.

Enhanced Network Security:

Security is paramount in industrial networking. Antaira prioritizes data protection by implementing features like Virtual LANs (VLANs), Access Control Lists (ACLs), and port security to safeguard against unauthorized access and potential cyber threats. This makes their switches ideal for applications in military installations, sensitive data centers, and critical infrastructure facilities.

Eco-Friendly Solutions:

Antaira takes sustainability seriously, and their Industrial Ethernet Switches are designed to be energy-efficient, resulting in reduced power consumption and lower environmental impact. Green initiatives in smart cities, renewable energy plants, and eco-sensitive regions can benefit significantly from the deployment of these eco-friendly switches.

Antaira’s commitment to excellence shines through their range of ATEX certified, Waterproof IP67, and IEC 61850-3 certified Industrial Ethernet Switches. The robust features, flexibility, and security they offer make them indispensable components in various industries and applications. As technology continues to evolve, Antaira remains at the forefront, providing innovative solutions that cater to the ever-changing demands of industrial networking.

Class1 Div 2 ATEX Industrial Ethernet Switches

In industrial environments where hazardous conditions prevail, safety and reliability are of utmost importance. Class 1/Div 2 ATEX certified Industrial Managed Ethernet Switches play a vital role in ensuring seamless communication and data transfer in such hazardous locations. These switches adhere to stringent safety standards, making them ideal for use in potentially explosive atmospheres.

Understanding Class 1/Div 2 ATEX Certified Industrial Managed Ethernet Switches

Class 1/Div 2 ATEX certified Industrial Managed Ethernet Switches are robust networking devices designed for use in hazardous areas. The ATEX certification ensures compliance with the European Union’s directive for equipment intended for use in potentially explosive atmospheres. The “Class 1” refers to hazardous locations where flammable gases, vapours, or liquids may be present, and “Division 2” signifies areas with the possibility of encountering hazardous materials under abnormal conditions.

These switches come equipped with advanced features that allow for efficient and secure data transmission in high-risk environments, while minimising the risk of electrical sparks or ignition sources. ATEX certification ensures that the switches have undergone rigorous testing and meet stringent safety standards to prevent accidents and protect personnel and assets.

Applications of Class 1/Div 2 ATEX Certified Industrial Managed Ethernet Switches

Oil and Gas Industry:

In the oil and gas sector, volatile substances are frequently present in drilling sites, refineries, and processing plants. ATEX certified switches facilitate communication between various components of the production process, ensuring smooth data flow, real-time monitoring, and control. They are crucial for process automation, safety surveillance, and remote management in remote and hazardous locations.

Chemical Industry:

Chemical processing plants involve handling hazardous chemicals and flammable substances. ATEX certified Industrial Managed Ethernet Switches play a critical role in supporting process control, supervisory control and data acquisition (SCADA) systems, and safety monitoring. They enable reliable and secure data transfer, reducing the risk of accidents and minimizing downtime.

Pharmaceutical Industry:

Pharmaceutical manufacturing environments often consist of hazardous substances. ATEX certified switches provide essential connectivity for process control, laboratory equipment, and compliance with regulatory standards. These switches ensure seamless communication and data integrity, critical for maintaining quality control and adhering to Good Manufacturing Practices (GMP).

Mining Operations:

Mining sites are characterized by challenging conditions, including the presence of combustible dust and gases. Class 1/Div 2 ATEX certified Industrial Managed Ethernet Switches support efficient data transmission for mining automation, ventilation control, and safety monitoring systems. They enhance productivity, optimize resource utilization, and improve overall safety in underground and surface mining operations.

Manufacturing and Processing Plants:

In manufacturing facilities where hazardous substances are used or produced, ATEX certified switches are essential for interconnecting machines, PLCs, robotics, and other devices. They enable seamless integration, leading to streamlined production processes, reduced downtime, and enhanced worker safety.

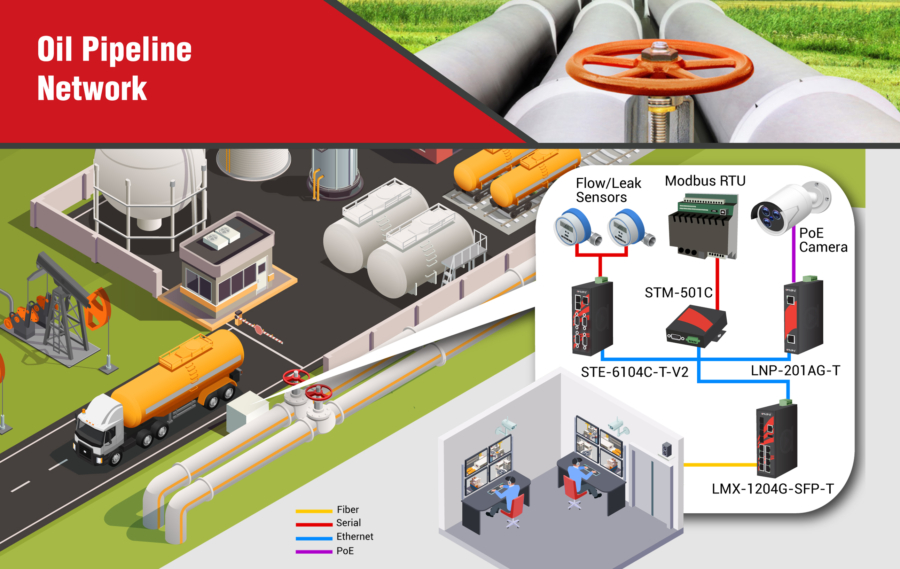

Oil and Gas Industry Application Examples (with Illustration)

Oil Pipeline

Oil pipelines form the backbone of the oil industry, facilitating the transportation of crude oil across vast distances. Ensuring the smooth operation and safety of these pipelines require sophisticated industrial networking equipment and robust monitoring systems. In this article, we will explore the critical role of industrial Ethernet switches in oil pipeline applications, where data is continuously collected, transmitted over long distances via fibre optics, and monitored from a central control room.

Oil Pipeline Monitoring and Control:

Overland oil pipelines rely on extensive networks that span across harsh terrains, making industrial networking equipment indispensable. These networks are integrated with thousands of data points distributed along the pipeline, which feed into a central control room. These data points provide essential information for monitoring the pipeline’s health and ensuring its smooth operation.

Industrial Ethernet Switches: Vital Components in the Process:

Industrial Ethernet switches play a pivotal role in the oil pipeline process, acting as key components in the data transmission and control mechanisms. At each field station, industrial Ethernet switches are deployed to boost and add new data streams to the network, allowing the continuous flow of critical information. These switches ensure that the data from remote field site stations is efficiently transmitted over long distances via fibre optics to reach the central control room.

Monitoring and Alert Systems:

The continuous stream of data collected from various sensors, including local Modbus and Ethernet sensors, along with video feeds from IP/PoE surveillance cameras, is vital for monitoring the pipeline’s health and integrity. These data streams encompass crucial information such as liquid flow rates, temperatures, pressure levels, and leak detection, all of which directly impact the safety and efficiency of the pipeline.

The collected data is transmitted across fibre optics that run the entire length of the pipeline, acting as the backbone of the application. This robust data transmission ensures that real-time information is available at the central control room, enabling operators to make informed decisions promptly.

SCADA System and Field Technicians:

The central control room is equipped with a Supervisory Control and Data Acquisition (SCADA) system, responsible for processing and monitoring the incoming data streams. Whenever an issue arises with a data point on the pipeline, the SCADA system promptly raises an alert. This alert allows operators to swiftly respond by contacting field technicians stationed along the pipeline to address the issue.

Enhanced Safety and Efficiency:

Industrial Ethernet switches in oil pipeline applications not only enable seamless data transmission but also contribute significantly to enhancing the safety and efficiency of the entire process. By continuously monitoring critical parameters, such as liquid flow, temperatures, and pressure, potential issues can be detected and addressed promptly, mitigating the risk of accidents and environmental hazards.

Moreover, the integration of video feeds from surveillance cameras enhances security and enables operators to quickly identify and respond to any potential threats or breaches along the pipeline route.

Summary:

Industrial Ethernet switches are indispensable components in the oil pipeline industry, enabling seamless data transmission and efficient monitoring of crucial parameters. The integration of fibre optics and advanced networking equipment ensures that data from remote field site stations reaches the central control room in real-time. By facilitating prompt responses to any detected issues, these switches enhance the safety, security, and overall efficiency of oil pipelines, making them an integral part of the oil industry’s success.

APPLICATION REQUIREMENTS

- Provide remote monitoring, access and control of field site equipment, and surveillance capability of pipelines from control centre.

- Network equipment that is suitable for wide temperature, high humidity, dust and even explosive environments.

- Fibre optics for long distance transmission of data across miles.

Offshore Platform

Oil remains a critical global resource that sustains various industries and economies. As over 70% of the Earth’s surface is covered by water, some of the richest oil reserves lie beneath the ocean floor. Extracting these underwater reserves poses significant challenges, but offshore oil platforms have proven to be a solution to this obstacle. These massive structures are equipped to drill wells and extract oil and gas from deep pockets beneath the ocean floor. To ensure safe and efficient operations, offshore platforms rely on industrial networking equipment for monitoring, control, and data transmission.

Industrial Networking on Offshore Platforms:

Offshore platforms are engineering marvels designed to tackle the complexities of drilling and extracting oil and gas from the depths of the ocean. A key aspect of these platforms’ success lies in the seamless integration of industrial networking equipment. This equipment enables real-time monitoring and control of devices from a central control room on the platform while transmitting critical data back to the mainland for upper management planning and decision-making.

SCADA Systems and Industrial Ethernet:

The oil extraction process on offshore platforms relies on Supervisory Control and Data Acquisition (SCADA) systems, which are networked using both serial (Modbus RTU) and Ethernet (Modbus TCP and other industrial Ethernet protocols) technologies. These SCADA systems play a crucial role in overseeing and optimizing the extraction process, ensuring maximum productivity and safety.

Industrial Ethernet Switches for Surveillance and Safety:

Safety is of paramount importance on offshore platforms, and IP/PoE surveillance cameras play a significant role in monitoring conditions throughout the platform. Industrial Ethernet switches are essential for providing the necessary connectivity and data transmission capabilities to these cameras. These switches enable real-time monitoring, allowing operators to promptly respond to any safety concerns or incidents that may arise.

Industrial Wireless Solutions for Connectivity:

Given the vast expanse of offshore platforms and the challenges posed by cabling in such environments, industrial wireless solutions become indispensable. These solutions provide WiFi connections to all on-board personnel and devices where cabling is not feasible or ideal. Industrial wireless solutions ensure seamless communication and connectivity, facilitating efficient data transfer and communication across the platform.

Summary:

Offshore oil platforms play a vital role in extracting oil and gas from underwater reserves, ensuring the continued supply of this critical resource. The success and safety of these platforms heavily rely on industrial networking equipment. From SCADA systems for monitoring and control to industrial Ethernet switches for surveillance and safety, and industrial wireless solutions for seamless connectivity, these components enable efficient operations and real-time data transmission. With Antaira providing complete industrial networking solutions, offshore platforms can operate with confidence, ensuring the steady flow of oil while adhering to strict safety standards.

APPLICATION REQUIREMENTS

- Continuous monitoring of devices and the ability to support high bandwidths

- Wide operating temperature for reliability in harsh environments

- Wireless link across oil platform

Benefits of Class 1/Div 2 ATEX Certified Industrial Managed Ethernet Switches

Enhanced Safety:

The primary advantage of ATEX certified switches is the enhanced safety they provide in hazardous environments. By preventing the occurrence of sparks and ignition sources, these switches significantly reduce the risk of explosions or fires, protecting both human lives and valuable assets.

Reliable Data Transmission:

Industrial Managed Ethernet Switches offer high data transfer speeds, low latency, and advanced Quality of Service (QoS) features. This ensures real-time data delivery, allowing for quick decision-making and efficient process control.

Robust Construction:

ATEX certified switches are built to withstand harsh conditions, including extreme temperatures, vibrations, and moisture. Their rugged construction ensures long-term reliability and reduces maintenance costs.

Easy Network Management:

Managed switches offer advanced network management features, such as VLANs, QoS, and security protocols, providing administrators with greater control over the network. This results in improved network performance and better resource allocation.

Waterproof IP67 and M12 Ethernet Switches

In industrial environments exposed to harsh conditions and extreme weather, reliable communication and data connectivity are paramount. Waterproof IP67 Industrial Managed Ethernet Switches with M12 Connectors offer robust networking solutions that can withstand challenging environments while ensuring seamless data transfer.

In this article, we will delve into what waterproof IP67 Industrial Managed Ethernet Switches with M12 Connectors are, explore their diverse applications, and highlight the benefits they bring to various industries.

Understanding Waterproof IP67 Industrial Managed Ethernet Switches with M12 Connectors

Waterproof IP67 Industrial Managed Ethernet Switches with M12 Connectors are durable and rugged networking devices designed to operate effectively in demanding industrial settings. The IP67 rating ensures the switches’ protection against dust ingress and temporary immersion in water, making them ideal for outdoor and harsh environments. The M12 connectors add further durability, providing secure and reliable connections resistant to vibrations and shocks.

These switches come equipped with advanced management features, allowing administrators to control and optimize network performance, prioritize data traffic, and ensure seamless data transmission across the network. The combination of waterproofing, M12 connectors, and network management capabilities makes these switches highly suitable for various industrial applications.

Applications of Waterproof IP67 Industrial Managed Ethernet Switches with M12 Connectors

Transportation and Railways:

In the transportation sector, including railways, waterproof IP67 switches play a vital role in connecting onboard systems, surveillance cameras, and passenger information displays. These switches endure the vibrations and extreme temperatures experienced in locomotives, railcars, and station environments. They ensure continuous data flow and reliable communication for improved passenger safety and operational efficiency.

Maritime and Offshore:

The maritime industry demands robust networking solutions due to exposure to saltwater, humidity, and constant movement. Waterproof IP67 switches with M12 connectors are essential for maritime vessels, offshore platforms, and ports. They support critical applications like radar systems, communication devices, and maritime automation, enhancing operational performance and safety.

Mining Operations:

Mining environments are characterized by dust, humidity, and rough conditions, making waterproof IP67 switches invaluable assets. These switches facilitate data transmission for mining automation, equipment monitoring, and safety systems. The M12 connectors provide secure connections that resist environmental challenges, ensuring uninterrupted operations and worker safety.

Outdoor Surveillance and Security:

For outdoor surveillance and security installations, these switches are the preferred choice. Their waterproof and rugged properties allow them to be deployed in remote locations, where protection against environmental elements is crucial. The M12 connectors ensure stable connections for IP cameras, sensors, and access control devices, enabling reliable monitoring and quick response to security events.

Industrial Automation:

In industrial automation, waterproof IP67 Industrial Managed Ethernet Switches with M12 Connectors serve as the backbone of the network. They connect programmable logic controllers (PLCs), robots, sensors, and Human-Machine Interfaces (HMIs) for streamlined production processes. The rugged design ensures constant connectivity, reducing downtime and optimizing productivity.

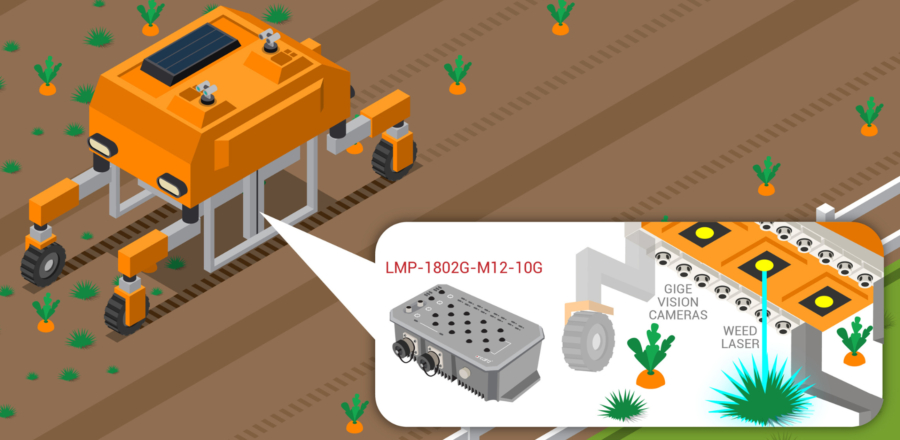

Industrial Automation Application Examples (with Illustration)

Agriculture Technology

In industries with harsh conditions and challenging environments, reliable and robust industrial switches are essential for seamless data transmission and efficient operations. Industrial switches with M12 connectors, etc, not only meet these requirements but also provide dust and water-tight connections, making them suitable for mounting in areas where few other devices could survive.

Benefits of M12 series of Waterproof IP67 Industrial Managed Ethernet Switches with M12 Connectors

Antaira’s IP67 M12 series of industrial switches are designed to withstand the rigors of demanding environments. With dust and water-tight connections, these switches can be mounted in locations where traditional devices may fail due to exposure to harsh elements. This feature makes them highly suitable for various industries, including agriculture, manufacturing, and transportation.

Factory Environment with Harsh Conditions:

Engineered to thrive in factory settings with challenging conditions, their robust construction ensures reliable performance, even in extreme temperatures, vibrations, and shock-prone environments.

High-Speed Connectivity:

Provides fast and stable connections, ensuring efficient data flow for real-time monitoring and control which for seamless data transmission from cameras to processors and actuators, high-speed connectivity is crucial.

Vibration and Shock Resistance:

In agricultural applications, where vehicles traverse farm fields all day, vibration and shock resistance are paramount. These switches will maintain a working system under such conditions, ensuring uninterrupted operations.

M12 Connectors for Dust and Water Protection:

The M12 connectors in Antaira’s switches keep dust and water away from sensitive connections, safeguarding the devices from potential damage and ensuring reliable connectivity.

Quick Maintenance and Design Changes:

The ability to operate without an enclosure offers flexibility for quick maintenance or design changes. This reduces downtime and facilitates efficient network management.

APPLICATION REQUIREMENTS

- Harsh Environment Industrial Grade Networking Devices: Antaira’s IP67 M12 series fulfils the requirements for rugged industrial networking devices, capable of withstanding challenging conditions.

- IP67 Rated Switch: The IP67 rating ensures dust and water resistance, making the switches suitable for deployment in various demanding environments.

- 10 Gigabit Fibre: For high-speed data transmission, Antaira’s IP67 M12 series supports 10 Gigabit fibre connections, enabling efficient data flow across the network.

- Vibration and Shock Resistance: The switches are designed to endure vibrations and shocks, making them ideal for applications in agriculture and other industries with dynamic conditions.

- High Working Temperature Design: Antaira’s IP67 M12 series is designed to operate reliably in high-temperature environments, ensuring continuous performance even in extreme conditions.

- 12-24 Volt DC Input Power: The switches support a wide range of input voltages, providing flexibility for power supply options in diverse applications.

- Wireless Connectivity: Antaira’s IP67 M12 series switches can integrate with wireless radios, enabling wireless connectivity for vehicles returning to the barn for refuelling or recharging.

Summary:

Antaira’s M12 series of industrial switches offer robust solutions for industries facing harsh conditions and challenging environments. With dust and water-tight connections, vibration and shock resistance, and high-speed data transmission capabilities, these switches ensure reliable and efficient operations. Whether deployed in agriculture or other industrial applications, Antaira’s M12 series provides a reliable networking solution that meets the demands of modern-day industries.

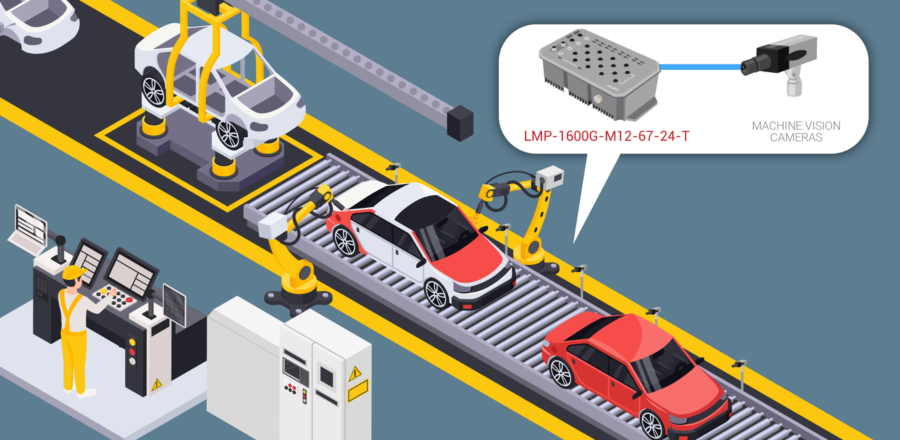

Factory Automation – Assembly Line

Machine Vision is rapidly gaining significance in automation applications, particularly in scenarios involving robotics. GigE Vision, a globally accepted communication protocol, has been widely adopted by machine vision camera manufacturers. This standard enables faster image transfers using standard cabling, but it comes with higher bandwidth requirements compared to previous generations of machine vision cameras. To simplify wiring, many GigE Vision cameras utilize Power over Ethernet (PoE) for power supply, streamlining the setup with just one cable. However, aggregating multiple GigE Vision cameras into an Industrial PC (IPC) often necessitates a 10G link from the PoE switch to the IPC running the software.

Challenges in Machine Vision Implementation:

Harsh Industrial Environment:

Deploying machine vision systems in industrial factory environments poses challenges due to harsh conditions. The networking equipment must be rugged and capable of withstanding extreme temperatures, vibrations, and shocks.

M12 Ethernet Connectors:

To ensure sensitive connections remain free from dust and water, M12 Ethernet connectors are employed, providing reliable and secure connections in challenging environments.

High-Speed Connectivity:

Efficient movement of data from machine vision cameras to the processor is vital for real-time performance. High-speed connectivity is essential to prevent data latency and ensure accurate automation.

PoE Power Supply:

Many GigE Vision cameras rely on PoE for power, streamlining installation with a single cable. Utilising an industrial switch with low voltage PoE support becomes imperative to power the high-speed cameras effectively.

APPLICATION REQUIREMENTS

- Harsh Environment Industrial Grade Networking Devices: Industrial-grade networking devices are indispensable for machine vision applications in demanding industrial settings, providing durability and consistent performance.

- IP67 Rated Switch: An IP67 rated switch offers dust and water resistance, making it ideal for deployment in challenging environments and ensuring reliable network connectivity.

- 10 Gigabit Fiber: The high bandwidth requirements of GigE Vision cameras necessitate the use of a 10 Gigabit fiber connection for efficient data transmission and real-time image processing.

- Vibration and Shock Resistance: Industrial networking devices must be designed to withstand vibrations and shocks encountered in the industrial environment, ensuring continuous operations and minimal downtime.

- 12-24 Volt DC Input Power: The networking devices should support 12-24 volt DC input power, providing flexibility in power supply options and compatibility with various equipment.

Summary

Machine Vision has become a critical component in automation applications, particularly in conjunction with robotics. GigE Vision has emerged as a global standard for communication, facilitating faster image transfers. Implementing GigE Vision cameras in automation systems requires robust networking solutions, with M12 Ethernet connectors for protection against dust and water, high-speed connectivity for efficient data transmission, and PoE support for streamlined power supply. With IP67 rated switches, 10 Gigabit fibre connections, and resistance to harsh conditions, industrial-grade networking devices meet the application requirements and enable seamless machine vision integration in challenging industrial environments.

Benefits of Waterproof IP67 Industrial Managed Ethernet Switches with M12 Connectors

Durability and Reliability:

The IP67 rating and M12 connectors ensure the switches’ resistance to water, dust, vibrations, and shocks, making them highly durable and reliable in harsh environments. This durability translates to longer operational lifespans and reduced maintenance costs.

Seamless Connectivity:

Waterproof IP67 switches guarantee uninterrupted data transmission, even in extreme conditions, thereby enhancing network stability and maintaining consistent communication between connected devices.

Improved Safety:

In hazardous industries, these switches provide critical network infrastructure that supports safety systems and remote monitoring. The reliable operation ensures timely response to potential hazards, reducing the risk of accidents and enhancing overall worker safety.

Flexible Deployment:

Due to their ruggedness and waterproof properties, these switches can be deployed in a wide range of applications, including outdoor and remote locations. This versatility allows businesses to expand their network infrastructure without concerns about environmental challenges.

Network Optimisation:

The managed capabilities of these switches enable administrators to control network traffic, prioritize data, and implement security measures. This leads to optimised network performance, improved data efficiency, and better resource utilisation.

Summary

Waterproof IP67 Industrial Managed Ethernet Switches with M12 Connectors offer a robust and reliable networking solution for industries operating in harsh environments. Their ability to withstand extreme conditions, combined with advanced management features, makes them indispensable in transportation, maritime, mining, security, and factory automation sectors. The benefits of durability, seamless connectivity, improved safety, and network optimization contribute to increased operational efficiency and cost-effectiveness. Investing in waterproof IP67 Industrial Managed Ethernet Switches with M12 Connectors ensures businesses can maintain continuous and secure data communication while thriving in challenging industrial settings.

IEC 61850-3 Certified Industrial Ethernet Switches

In the world of industrial automation and power utility systems, reliable communication and data transmission are essential for seamless operations. IEC 61850-3 certified Industrial Managed Ethernet Switches have emerged as critical networking solutions that meet the stringent requirements of these industries. This article will delve into what IEC 61850-3 certified Industrial Managed Ethernet Switches are, explore their diverse applications, and highlight the significant benefits they bring to industrial and utility sectors.

Understanding IEC 61850-3 Certified Industrial Managed Ethernet Switches

IEC 61850-3 certified Industrial Managed Ethernet Switches are robust networking devices designed to comply with the International Electrotechnical Commission (IEC) standard 61850-3. This standard specifically addresses the communication and interoperability requirements for substation automation systems in power utility applications. These switches provide reliable, high-speed data transmission, ensuring smooth communication between various components in industrial automation and power utility networks.

APPLICATION REQUIREMENTS

- Power Utility Substation Automation: In power utility substations, precise and real-time data exchange is critical for efficient monitoring and control. IEC 61850-3 certified Industrial Managed Ethernet Switches play a vital role in facilitating secure and rapid communication between Intelligent Electronic Devices (IEDs), such as protection relays, circuit breakers, and meters. They ensure reliable substation automation, enabling utilities to respond promptly to grid events and prevent potential power disruptions.

- Smart Grid Systems: The integration of renewable energy sources, such as solar and wind, into the power grid necessitates smart grid systems. IEC 61850-3 certified switches enable seamless communication between smart meters, distribution automation devices, and the utility’s control centre. These switches support the efficient management and optimization of power generation, distribution, and consumption, promoting energy efficiency and sustainability.

- Industrial Automation and Process Control: In manufacturing and process industries, IEC 61850-3 certified switches facilitate the integration and networking of Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and other automation devices. They provide real-time data transfer, enabling precise process control, remote monitoring, and predictive maintenance, thus improving productivity and reducing downtime.

- Transportation and Infrastructure: IEC 61850-3 certified switches find applications in transportation systems, such as railways and metro networks. They support reliable communication between signaling systems, control centers, and train control systems, enhancing safety and efficiency in transportation operations.

- Intelligent Building Networks: In modern intelligent buildings, efficient networking is essential for building automation, security, and energy management systems. IEC 61850-3 certified switches offer reliable communication between various building systems, ensuring smooth operations and energy optimisation.

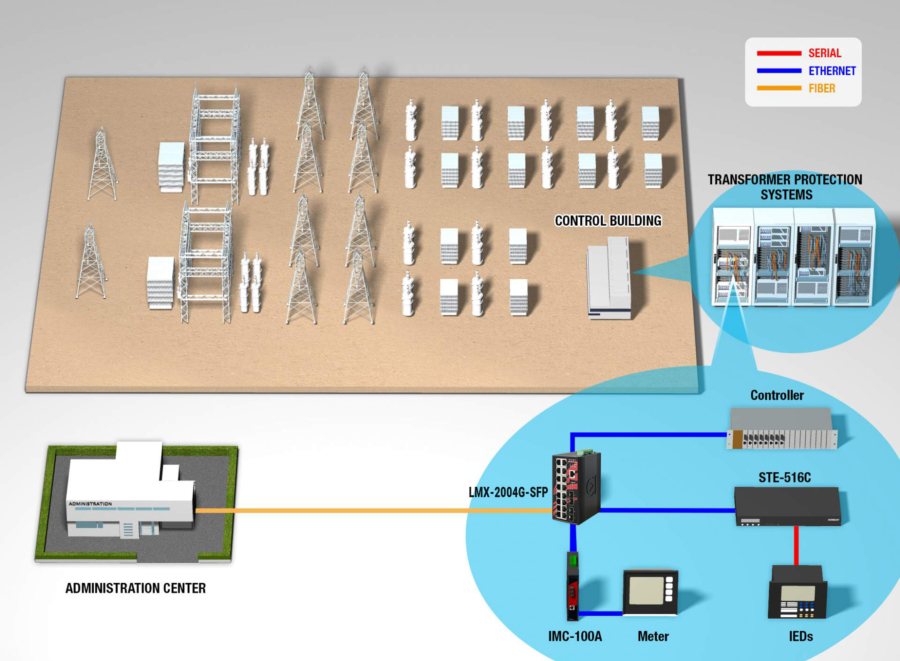

Power Utility Substation Automation Application Example (with Illustration)

Electrical substations play a crucial role in the power grid, facilitating the transfer of electricity from high-voltage transmission lines to lower voltage distribution lines for public use. These substations heavily rely on industrial-grade networking devices to ensure the power grid operates with minimal downtime and interruptions. This article will explore the significance of industrial networking solutions in substations, the components involved, and the essential requirements for efficient operations.

The Role of Industrial Networking in Substations:

Each electrical substation features a control building housing transformer protection systems, which are interconnected within large metal enclosures. These enclosures contain main controllers that utilize industrial Ethernet switches and serial devices to monitor meter and Intelligent Electronic Device (IED) data. This data is transmitted via fibre optics to an administrative centre, enabling remote monitoring, access, and control of transformer protection systems.

Industrial Ethernet Switches and Serial Devices:

Industrial Ethernet switches and serial devices are critical components of the control systems in electrical substations. The use of industrial-grade equipment ensures seamless data transmission in real-time, allowing for efficient monitoring and control of vital substation processes. These switches provide robust networking capabilities, enabling data exchange between main controllers and various devices, even in harsh environmental conditions.

Remote Monitoring and SCADA Systems:

At the administrative centre, Supervisory Control and Data Acquisition (SCADA) systems play a pivotal role in closely monitoring substation equipment. These systems continuously collect data and trigger alarms in case of any anomalies or events. Administrative centre workers have the capability to monitor power flow and control breakers, allowing them to perform necessary actions like opening and closing breakers as needed.

APPLICATION REQUIREMENTS

- Real-Time Seamless Data Transmission: Substation operations demand real-time data transmission for precise monitoring and rapid responses to critical events. Industrial networking solutions equipped with high-speed data transfer capabilities ensure minimal latency, enabling efficient control and management of substation processes.

- Harsh Environment Resilience: Electrical substations are often exposed to harsh environmental conditions, including extreme temperatures, vibrations, and humidity. Industrial networking devices must be designed to withstand these challenges and maintain consistent performance under adverse circumstances.

- Hardened and Reliable Network Infrastructure: A hardened and reliable network infrastructure is vital for substations to ensure uninterrupted communication and data flow. Industrial-grade switches and devices provide a robust network foundation, reducing the risk of network disruptions and downtime.

- Legacy Serial Device Compatibility: Many substations still use legacy serial IEDs and meters for monitoring and control. An effective networking solution must incorporate compatibility with these legacy devices, allowing seamless integration with modern Ethernet-based systems.

Summary:

Industrial networking solutions are essential for the seamless operation and safety of electrical substations. These solutions facilitate real-time data transmission, robust networking capabilities, and compatibility with legacy devices, ensuring efficient monitoring, control, and protection of transformer systems. With industrial Ethernet switches and serial devices playing a critical role in substation networking, the power grid cycle can run smoothly with minimal downtime, safeguarding a reliable and continuous supply of electricity to the public. Embracing industrial networking solutions empowers substations to maintain efficient operations, improve productivity, and enhance the overall reliability of power distribution systems.

Benefits of IEC 61850-3 Certified Industrial Managed Ethernet Switches:

Robust Design:

IEC 61850-3 certified switches are designed to withstand harsh environmental conditions, making them suitable for deployment in challenging industrial and utility environments. They offer high levels of shock, vibration, and temperature resistance, ensuring consistent performance.

Enhanced Network Reliability:

These switches provide redundant ring or mesh network topologies, ensuring high network availability and fault-tolerant communication. Redundancy mechanisms protect against single point failures, minimizing downtime and ensuring uninterrupted operations.

Secure Communication:

IEC 61850-3 certified switches support advanced security features, such as VLANs, Access Control Lists (ACLs), and encryption protocols, safeguarding critical data and protecting against unauthorized access or cyber threats.

Precise Time Synchronization:

Time synchronisation is crucial in industrial and utility applications for accurate event logging and control coordination. These switches support Precision Time Protocol (PTP) and other synchronization mechanisms, ensuring precise and synchronized data exchange across the network.

Remote Management and Monitoring:

Industrial Managed Ethernet Switches offer advanced management features, allowing administrators to remotely configure, monitor, and diagnose network devices. This facilitates efficient network maintenance and reduces operational costs.

Summary

IEC 61850-3 certified Industrial Managed Ethernet Switches have become indispensable components in industrial automation and power utility applications. Complying with the IEC 61850-3 standard, these switches ensure reliable and secure communication, promoting efficient substation automation, smart grid systems, industrial automation, and more. The robust design, network redundancy, enhanced security, precise time synchronization, and remote management capabilities make IEC 61850-3 certified switches highly advantageous in demanding industrial and utility environments. Embracing these advanced networking solutions empowers industries to achieve seamless operations, improved productivity, and enhanced safety, driving the future of automation and smart energy systems.