In this article:

An Engineering Guide To Purge and Pressurization Systems

Assured Systems have years of experience in applications requiring purging and pressurization. Learn and understand more about this technology.

The need to place general-purpose equipment in hazardous (classified) locations is not new, yet in the last three decades, the need has intensified dramatically. This is primarily due to the following facts:

- Process control, measuring and recording equipment that was once primarily pneumatic is now primarily general-purpose electronic equipment.

- Motors and switch gears now use electronic accessories to satisfy the needs for position, speed or process control and energy efficiency, which often renders the equipment unsuitable for use in hazardous locations.

- Newly developed equipment, such as robotic manipulators, CNCs, batch weigh/count and filling systems, analyzers, programmable controllers, and CRT work stations, are rapidly becoming more prevalent in the industrial work environment.

While the demand for these new devices continues to grow, most of them cannot be economically installed in a hazardous location by using explosion-proof enclosures or intrinsic safety barriers, alone. Most modern electronic equipment is expensive and delicate. For this reason, it requires environmental protection that cannot be provided by explosion-proof enclosures or intrinsic safety barriers. Therefore, the need for an alternative to explosion-proof enclosures and intrinsic safety barriers has become extremely critical.

The alternative is purge and pressurization. As you learn more about purge and pressurization, it will become apparent that this technology is precisely what you require. It will then become evident that this technology offers the safest and most economical means of installing electrical equipment in a hazardous location.

Explosion Proof Enclosures

These enclosures are designed to contain an explosion if an electrical device ignites flammable substances within the enclosure, thus preventing ignition of the surrounding atmosphere. These enclosures are commonly used for circuit breakers, mechanical switch gears, and high-powered equipment. The failure to properly tighten all bolts and screw covers on these enclosures is the greatest problem facing end-users.

Advantages

- Explosion Containment

- No Electronics

- Requires Low Maintenance

- No Moving Parts

- High-Powered Equipment

Disadvantages

- Cannot Indicate Failure of Containment Capability

- Danger to Equipment After Explosions

- Possibility of Installation/Maintenance Errors

- Cost of Protection per ft3 Increases with Enclosure Size

- Windows Are Limited

- Promotes Condensation

- Limited Sizes

- Cumbersome, Limited Access

- Bulky Designs

- Causes Harmful Heat Build up

- Excessive Weight

Intrinsic Safety Barriers

These devices are designed to limit the current and voltage conducted through a device’s power or signal wiring. This limitation prevents shorting and arcing of the wires or device, thus preventing ignition of the surrounding atmosphere. They are commonly used for protection of instruments that operate at extremely low power levels and are suitable for exposure to the environment.

Advantages

- The Only Protection Allowed for Zone 0

- Eliminates the Possibility of Explosion

- No Hot Permits

- Requires Low Maintenance

- No Special Cables

- Ideal for Low-Power Devices

- Limits Energy to Device

Disadvantages

- Requires Documentation of I.S. Circuits and Installation

- Can be Used Only with Low-Power Devices

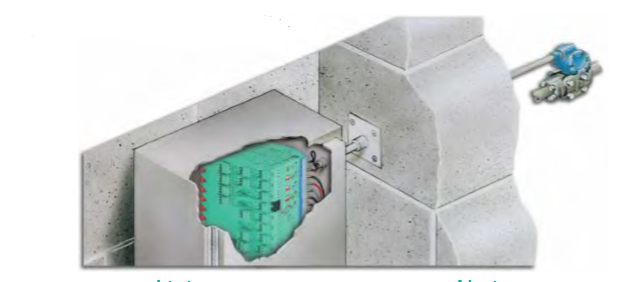

Enclosure Protection Systems

These systems are designed to supply one or more protected enclosures with clean instrument air or inert gas. This process removes flammable gases or prevents the accumulation of ignitable dust within the protected enclosure(s). This method of protection is not limited by the quantity, configuration, power requirements, or location of the protected equipment. These systems are commonly used for all applications involving basic electronics, electrical equipment, motors, and switchgear.

In addition, these systems can also meet the demands of rack-mounted instrumentation, video displays, programmable controllers, computers, printers, recorders, measurement devices, gas analyzers, and calibration equipment. One of the best benefits is the slow but continuous flow of protective gas, which can be specifically used to eliminate problems like heat, moisture, dust, and corrosion. Moreover, unlike explosion-proof enclosures, failure of an Enclosure Protection System does not create an immediate danger.

Advantages

- Reduces Heat Build up

- Inhibits Metal Corrosion

- Requires Low Maintenance

- Increases Equipment Longevity

- No Special Enclosures Required

- Allows Fast Access to Equipment

- Reduces Moisture & Dust Build up

- Reduces Classification within the Enclosure

- Continuous System Status Indication

- Protects Enclosures up to 450 ft3

- Allows use of any Enclosure Shape

- Cost of Protection per ft3 Decreases with Enclosure Size

Disadvantages

- Contains Moving Parts

- Requires Instrument Air Supply

- Some Systems Require Electronics

- Hot Permits Required

Defining Hazardous Areas

Today’s modern refineries and manufacturing complexes often contain both flammable gases and ignitable dust, making area classification of Division 1 and Division 2 locations an important but tricky task.

Hazardous (classified) locations are those areas in an industrial complex where the atmosphere contains flammable concentrations of gases or vapors by leakage or ignitable concentrations of dust or fibers by suspension or dispersion.

The National Fire Protection Association (NFPA), formed in 1896, is a non-profit organization devoted to fire safety standards and codes. It currently retains over 40,000 members who work to determine safe practices and establish standards for all areas of commercial, industrial, and residential construction. They publish many documents including NFPA 70 – better known as the National Electric Code and NFPA 496 – the document that specifies recommended practices for pressurization and purging.

Area Classification Methods

The NFPA establishes area classifications using three factors. Identified as Classes, Groups and Divisions, these factors are combined to define conditions of specific areas.

Important Notes: Division 1 areas must be surrounded by Division 2 areas.

Class Ratings

Classes are used to define the explosive or ignitable substances that are present in the atmosphere.

Class I – Flammable gases or liquid vapor.

Class II – Ignitable metal, carbon or organic dusts.

Class III – Ignitable fibrous materials.

Group Ratings

Groups are used to define substances by rating their explosive or ignitable nature, in relation to other known substances.

TYPICAL CLASS I SUBSTANCES

Group A – Acetylene

Group B – Hydrogen or > 30% Hydrogen by Volume

Group C – Ethyl Ether & Ethylene

Group D – Acetone, Ammonia, Benzene & Gasoline

TYPICAL CLASS II SUBSTANCES

Group E – Aluminum, Magnesium & Alloys

Group F – Carbon, Coke & Coal

Group G – Flour, Grain, Wood, Plastic & Chemicals

Division Ratings

Divisions are used to define the degree of hazard by determining the explosive or ignitable substance’s expected concentration in the atmosphere.

Division 1 – Contains substances under normal conditions

Division 2 – Contains substances under abnormal conditions

Zone Ratings

Zones are used to define the degree of hazard by determining the explosive or ignitable substance’s expected concentration in the atmosphere.

Zone 0 – Contains substances under normal conditions (Continuously)

Zone 1 – Contains substances under normal conditions (Intermittently)

Zone 2 – Contains substances under abnormal conditions

Here is a more in-depth technical article about ATEX Class, Division and Zone Ratings.

Common Questions

What is purging?

Purging is the process of supplying enclosures with compressed air or inert gas at the proper flow and pressure in order to reduce the hazardous gas inside the enclosure to a safe level. Pressurization is the process of bringing compressed air or inert gas within an enclosure to a pressure where there is no ingress of hazardous gasses or combustible gas. Both purging and pressurization are required in a Class I, gas atmosphere. Only pressurization is required in a Class II, dust atmosphere.

What is used to purge/pressurize?

The most common and practical protective gas is compressed instrument quality air that contains no more than trace amounts of combustible vapor. Inert gases, such as nitrogen or argon, are acceptable. Although they are usually expensive and impractical, they may be required for some gas analysis applications.

What is the pressure requirement?

Most purging applications require a minimum enclosure pressure of 0.10 inches (2.5 mm) of water. One psi is equal to 27.7 inches of water. In some circumstances, a minimum enclosure pressure of 0.50 inches (12.7 mm) of water is required to protect against ignitable dust. However, in all cases, a higher enclosure pressure should be maintained to create a reasonable safety factor. In rare circumstances, enclosure pressures as high as 2.5 inches (63.5 mm) of water may be required to offset sudden atmospheric pressure fluctuations, such as those created near missile launching or off-shore drilling platforms.

How much purging gas is used?

Average protective gas consumption during pressurization at a 0.10 inch (2.5 mm) enclosure pressure should fall somewhere between 0.1 to 3.5 SCFH per cubic foot (2.83 to 99.11 l/hr) of enclosure volume. However, use will depend on the protected enclosure’s integrity and normal pressure setting. Use is also dependent on the quantity and size of covers and doors as well as devices which penetrate the surface. Advanced forms of protection such as cooling or dilution may require continuous flow rates of 30 to 100 SCFH (849.38 to 2831.26 l/m). Purging requires a much higher flow rate than pressurization, but only for a short period of time.

What kinds of enclosures can be purged?

Any enclosure can be purged, but enclosures featuring gasketing and multiple door fasteners are ideal. Therefore, in the absence of official construction requirements for purged enclosures, we recommend enclosures which meet or exceed the National Electrical Manufacturer’s Association rating of NEMA 4 or NEMA 12.

What kinds of devices can be purged?

Virtually any basic electrical device can be purged, if all “live” or energized components can be isolated from the surrounding environment. Devices such as pushbuttons, relays, timers and programmable controllers only need to be installed in a sealed enclosure. Motors only require a totally enclosed housing.

How can the equipment be accessed?

Equipment mounted in the protected enclosure can be accessed if the area is known to be non-hazardous, or if all power to the protected equipment has been de-energized. In other words, internal equipment should be treated as if located in an explosion-proof enclosure. However, a cooling period may be required before accessing hot components, such as transformers or variable speed drives, which would otherwise be unacceptable for use in the hazardous location.

Equipment mounted through the surface of a protected enclosure may require a sealed access door if the equipment is not suitable for exposure to the surrounding atmosphere. Advanced pressurization systems, like Rapid Exchange Purging Systems can maintain a positive pressure, by increasing the flow of protective gas while the access door is open.

NFPA & ISA Design Standards

Pressurization Standards

Committee SP12 of the Instrument Society of America (ISA) established the first Design Standard in 1966, entitled “ISA s12.4 – Instrument Purging For Reduction Of Hazardous Area Classification.” In 1967, the NFPA Technical Committee on Electrical Equipment in Chemical Atmospheres established recommended practices, entitled “NFPA 496 – Purged and Pressurized Enclosures for Electrical Equipment.” Since then, the NFPA has expanded their document by adding recommendations for enclosure ventilation and dilution.

The NFPA document is the American standard for the design, marking and performance of enclosures and pressurization systems. The ISA document addresses construction, installation and testing of protected enclosures and pressurization systems.

Pressurization “Types”

The NFPA and ISA define “Types” of pressurization based on the Division rating of a hazardous location and electrical ratings of the protected equipment. General-purpose and Division 2 rated electrical equipment require different means of protection, depending on their location.

Type “X”

Protects general-purpose equipment in Division 1 Areas. This system reduces the classification within protected enclosures from Division 1 to non-hazardous. It is required to automatically control electrical power to all protected equipment.

Type “Y”

Protects Division 2 rated equipment in Division 1 Areas. This system reduces the classification within protected enclosures from Division 1 to Division 2. All protected equipment must be rated for Division 2. Automatic power control disconnects are not required, but visual and/or audible alarms must be initiated when there is loss of pressure.

Type “Z”

Protects general-purpose equipment in Division 2 Areas. This system reduces the classification within protected enclosures from Division 2 to non-classified. Automatic power control disconnects are not required, but visual and/or audible alarms must be initiated when there is loss of pressure.

Purging and Pressurizing Methods

The NFPA and ISA define several techniques for protecting equipment. Most equipment requires only basic pressurization in Class II areas or purging in Class I areas. Ventilation and dilution are advanced protection methods for heat-producing or flammable gas analyzing equipment.

Purging Common equipment in Class I Areas

As strictly defined by NFPA 496, this method is a start-up process of Class I area pressurizing which removes flammable vapors from a protected enclosure. This is accomplished by exchanging a known volume of protective gas, while maintaining a minimum positive enclosure pressure of 0.10 inches (2.5 mm) of water. The 2003 edition of NFPA 496 recommends 4 volume exchanges for all enclosures and 10 volume exchanges for all motors.

Pressurization Common equipment in Class I & II Areas

This method prevents the entrance of flammable gas or combustible dust into protected enclosures. In Class II areas, this is accomplished by manually removing any dust and then applying a protective gas supply to maintain a positive enclosure pressure of 0.50 inches (12.7 mm) of water. In Class I areas, this is accomplished by “purging” as defined below, and by then maintaining a minimum positive enclosure pressure of 0.10 inches (2.5 mm) of water. Power can then be applied to the protected equipment under conditions established by the Division rating.

Ventilation Hot equipment in Class I & II Areas

This method provides protection as outlined above and also removes or dissipates heat from electrical devices within a protected enclosure. This method is commonly used to cool equipment or reduce enclosure surface temperatures. Ventilation requires high airflow and is commonly performed with blowers for high voltage switchgear devices.

Dilution Analytical equipment in Class I Areas

This method provides protection as outlined above and continuously removes or dissipates flammable gases within a protected enclosure. Dilution may require the use of nitrogen to blanket the enclosure. Otherwise, a higher flow of instrument air will likely be required.

Discuss Your Purge and Pressurization Application With Assured Systems

Assured System’s sales team in both the UK & USA have years of experience in applications requiring purging and pressurization. We thoroughly understand our products, our customers, and the applications in which our systems are being deployed. You can rely on our expertise to ensure you receive the right guidance resulting in a precise fit for your requirements every time, saving you time and effort, and ultimately money. If you have an application you would like to discuss, please call +44 1785 87 90 50 (EMEA) or +1 864 421 6991 (USA) or use the contact form to send us your requirements.